Sustainability practices continue to gain momentum as this consumer trend rises in popularity. For CPGs, sustainable business practices reflect more than just a conscientious way of doing business. They represent the values we have as consumers for sustaining the environment for future generations. We’d like to offer some thoughts regarding milk containers as they relate to recyclability, whether it be a circular or a recycling economy.

According to Nielsen, the U.S. sustainability market is projected to reach $150 billion in sales by the end of 2021. Consumers have never been more discriminating than they are today. Having a great product is no longer enough to attract new customers.

Consumers want to know where their products come from, how they are made, and where the packages end up. Consumers will make purchasing decisions (and non-purchasing decisions) based on the answers to these questions.

How does this affect PET and HDPE milk containers?

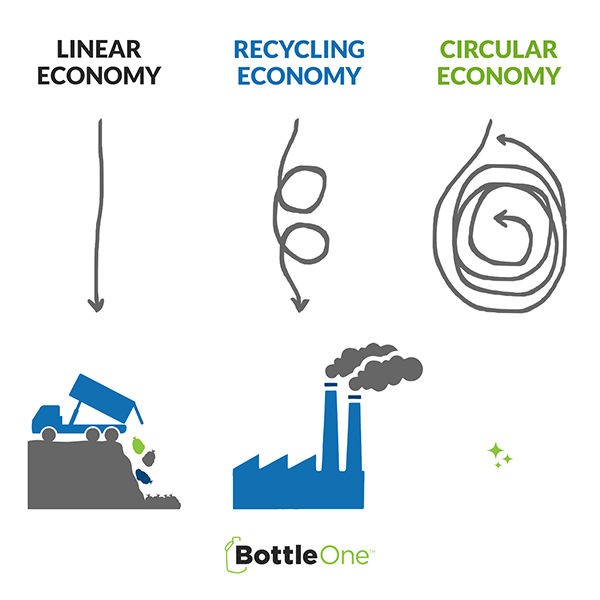

The Difference Between a Circular and a Recycling Economy / Down-Cycling Economy

Often times, a recycling economy is described as a “down-cycling or open loop” method of manufacturing. Like the phrase implies, a recycling economy is a process of making products that get used once, and then if properly disposed of can be made into something else less technical and then thrown away.

In other words, all raw materials used to produce the product are sooner or later discarded. The recycling economy method feeds the myth that natural resources are unlimited. If we continue this down-cycling method, over time, our planet will be unable to sustain itself.

Throughout the years, most manufacturing methods have relied upon either a linear economy or down-cycling philosophy. As a result, we’ve filled landfills with waste, or polluted the air by incinerating the waste and put a strain on our natural resources.

On the other hand, a circular economy is based on products and raw materials being reused over and over. The phrase often associated with a circular economy is “upcycling and closed-loop.”

This method of manufacturing “closes the loop” since everything keeps moving in a productive cycle instead of turning into garbage. It prevents waste and harmful emissions from polluting our landfills, water and air. It preserves our planet for future generations.

As you see in the image above, a recycling economy is different than a circular economy. In a recycling economy, we still end up with waste. In a circular economy, products are created for unlimited lifetimes. Waste is eliminated altogether.

How Is This Related to PET and HDPE Milk Containers?

Although HDPE milk containers are recyclable, a circular economy for HDPE does not currently exist. For example, the plastic in a HDPE milk jug might be recycled into a pipe or into carpet. But in the end, it still creates waste.

In other words, HDPE is down-cyclable. At some point, HDPE plastic is either incinerated or goes into the ground. There’s no market to get it back to where it once was. The sobering truth is that the majority of HDPE milk containers are buried in landfills.

What Is the Solution?

There’s a simple solution to this complex problem. Change your container to a BottleOne PET container.

PET is unique among plastics, and it creates a unique opportunity.

Not only do BottleOne’s PET containers offer better economics, better flavor and better nutrition, they support a circular economy.

In PET, there is a circular economy with pent up demand and extremely attractive economics to put it right back into the cycle and close the loop. You can read more about this in Plastic Is the Unexpected Solution to the Plastic Problem.

Companies are waiting to reuse your PET. Please don’t throw it on the side of the road, or put it in the trash. Someone is trying to buy your PET bottles, please put them into the blue recycling bins.

How Do We Make This Happen?

If we can migrate milk packaging into PET (BottleOne is the enabler to do that), we will take the scope and scale of the circular economy to PET. It will explode from there!

The volume of plastic used in dairy packaging is enormous. Introducing that into the PET circular economy will supercharge it. Together, we can hyper-drive the circular economy and make recycled PET resin more accessible for all manufactures to reuse.

How Will It Work?

The conversion of dairy packaging to PET is not only inevitable, it is irreversible. Once every family understands their contribution to the circular economy, they will never go back to a plastic product that doesn’t have a recycle code 1 (PET) on the bottom.

If we can get all liquid dairy into recycle code 1 containers, we can get all of those containers into the circular economy. That will be the driving force behind all the sustainability efforts necessary to deal with what’s called the “plastic problem.”

What about in the Developing Countries Where Trash Is Still Being Tossed into the Rivers?

We need to export our circular economy into those communities. We can prove and demonstrate the technology necessary to return PET packaging to PET resin in those developing countries. We will be able to take the technology from our own communities halfway around the world and eliminate PET garbage.

The Best Way to Reduce Your Sustainability Footprint is to Package Your Dairy in PET Milk Containers

By using BottleOne’s PET bottles, you will also eliminate secondary packaging. The number one way to make the biggest sustainability impact is to change all of your plastic packaging to PET. Get started by purchasing your milk products in BottleOne PET milk containers.

Is Migrating to BottleOne PET Milk Containers Costly?

The operating model that produces and delivers BottleOne has very favorable economics relative to what it replaces. When we look at the cost modeling based on the delivered product, in every case we’ve seen so far, the conversion to BottleOne has saved the producer money.

BottleOne generates favorable economics while enabling the kind of circular economy that PET provides.

There are many reasons that point to why you would want to use BottleOne, whether it is the circular economy, the elimination of secondary packaging or the fact that milk just tastes better when packaged in PET.

BottleOne is tailored to today’s consumer. It’s new, innovative, and it creates many opportunities. This is true whether you are the consumer or the retailer that adopts the technology.

We believe that transitioning from the current HDPE bottle to PET will be the catalyst to take this circular economy global. Let’s allow the economics of the market to fund that responsible environmental behavior.

We have the ideal conditions right now to execute this. BottleOne is the technology that enables it in dairy, and that’s why we are so excited about the conversion of the dairy business.

Our society will never go back to throwing a milk bottle in a landfill after experiencing BottleOne.

Let us show you how BottleOne will improve your operating efficiencies and increase your profitability

BottleOne is an affordable large capacity, standard grade PET bottle with an integrated PET handle. BottleOne is designed to dramatically impact your supply chain. Let us introduce you to this 21st century operating model.

0 Comments