It’s just beautiful

BottleOne is a large capacity, PET bottle with an integrated PET handle

What makes it so special is how this technology will impact your bottom line

Production

- Corrugated Savings

- Corrugated Storage Savings

- Potential Resin Savings

- Increased Production Efficiency

- Faster Run Times

- Produce More in the Same Footprint

- On Demand Manufacturing

- Accurate Fill Height

- Reduced Bottle Leaks

- Reduced Mess

- Reduced Production Sanitation

Distribution

- Better Distribution Efficiency

- Increased Bottle Durability

- Reduced Warehouse Space

- Faster Truck Loading

- Dock Door Efficiency

- Optimizes Fleet Efficiency

- Reduced Shipments/Emissions

- Reduced Bottle Leaks

- Reduced Mess

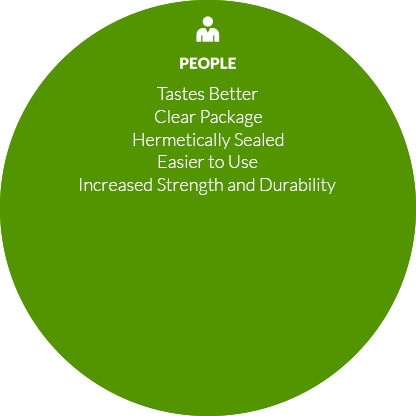

Consumption

- Improved Consumer Perception

- Bottle Clarity

- Improved Taste

- Retained Nutrition

- Reduced Product Degradation

- Increased Retail Efficiency

- Reduced Bottle Leaks

- Increased Bottle Durability

- Reduced Corrugate Handling

- Reduced Corrugate Recycling

- Reduced Corrugate Storage

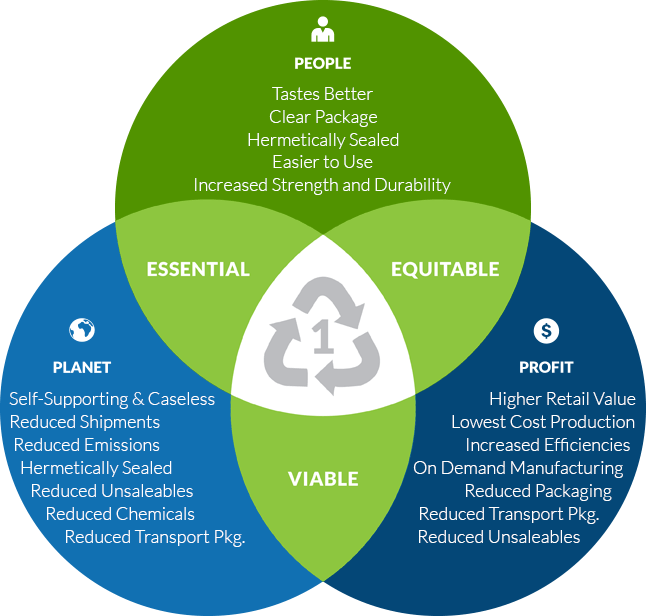

IMPROVE OPERATING EFFICIENCY, REDUCE COSTS, AND DELIGHT CUSTOMERS WHILE LOWERING YOUR CARBON FOOTPRINT

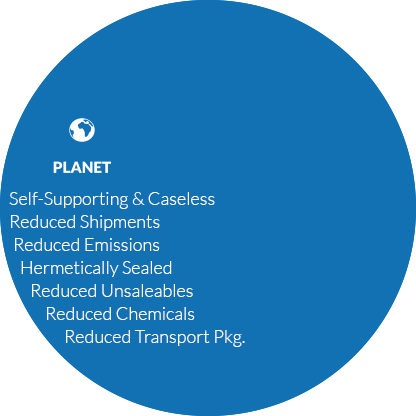

Environmental

PET is the most recycled and recyclable plastic in the world.

BottleOne containers are so strong and durable that they can be stacked on top of each other without the need for cardboard boxes or crates.

Some BottleOne users have found:

- Gallon HDPE jugs that require corrugated boxes to ship pallets with 4 layers have been replaced by BottleOne gallon jugs in bundles that can be palletized with 5 layers, and those 5-high pallets can be stacked 2 high.

- Corrugated usage is reduced by more than 60-90%.

- Climate controlled warehousing space can be cut by 60%.

- Trucks that were maxed out on floor space with 4-high pallets can now be maxed out on weight which means 25% more product can be shipped per truck vs. HDPE bottles, eliminating 25% of current emissions.

Endlessly Sustainable

BottleOne’s processes and equipment can handle any level of PCR. BottleOne containers are designed to be caseless, and will enable elimination of most secondary packaging due to their inherent strength and durability. If PCR content negatively affects strength and durability, we will adapt our designs and processes to mitigate them in order to keep secondary packaging minimized. The door to circularity swings only one way, opening to the future, and will not permit a return to the past. PCR is here to stay.

No Leaks, No Contamination

BottleOne’s excellent barrier properties, and its neck and cap seal, improve product security. It seals hermetically, eliminating leaks that are endemic to current HDPE packaging. This reduces the mess in production, in the dairy case and in the consumer’s home. It also expands sales and geographic distribution limits currently placed upon many production facilities, as they can ship farther without product loss or damage. Now that large capacity bottles don’t leak, they can easily be included in last-mile deliveries, whether through a personal service or drone delivery.

Improved

Taste Profile

We already know that multiple variables can influence product quality, including microorganisms, light, oxygen and temperature. PET barrier solutions improve product safety with good oxygen barrier properties – 50 times higher than HDPE (high density polyethylene). Studies have demonstrated that products taste better when they are packaged in PET.

Retains more

nutrition

The same variables that ensure your products taste better also help them retain better nutrition than regular HDPE jugs. A Virginia Tech Study proves that 2% milk, packaged in PET, retains more nutrition and tastes better than products packaged in standard HDPE bottles. Many other beverage products, particularly plant-based beverages like tea and juice contain the same vitamins and nutrients that are found in milk, and it is logical to believe that the flavor and nutrition benefits gained by milk in PET will impact those products in similar ways.

Balancing economic, social and environmental sustainability factors in equal harmony

Just one (of many) BottleOne savings opportunities

Here is a fraction of the total sustainability savings available to you.

By converting one million corrugated boxes to tray pack, you will save:

TONS OF PAPER

4,855.2

TREES

GALLONS OF WATER

KWH OF ELECTRICITY

GALLONS OF OIL

Situation

Your Bottle Needs to Change…

By changing your bottle… you incorporate new ideas and technologies to meet the needs of today’s marketplace.

For decades, designers and packaging makers have been trying to figure out how to create a cost-effective, one-piece, PET bottle with a handle for mass production. After 55 years of HDPE gallon and half-gallon jugs, it’s here. Introducing BottleOne, a standard grade PET bottle created on established manufacturing platforms, and blow molded with an integrated PET handle.

By changing your bottle… the delicious taste and natural nutrition profiles will be preserved.

We know that multiple variables can influence product quality, including microorganisms, light, oxygen and temperature. PET barrier solutions improve product safety with good oxygen barrier properties – 50 times higher than HDPE. The same variables that ensure your products taste better also help them retain better nutrition than regular HDPE jugs. A Virginia Tech Study proves that 2% milk, packaged in PET, retains more nutrition and tastes better than products packaged in standard HDPE bottles.

By changing your bottle… there are no leaks, no mess, and no smell.

Large bottles leak everywhere – in production, in transportation, in the dairy case (stinky!), in consumers’ cars, homes and refrigerators. If you drop a bottle, the bottle may split and the lid pop off (messy!). Customers expect more, and deserve more, from a container that delivers their family’s first drink of the day.

By changing your bottle… 60% – 90% of the secondary packaging is eliminated.

The packaging required to get traditional smelly, messy bottles to retail is extensive: crates, cardboard boxes, stretch wrap, etc. Purchasing, handling, warehousing and disposing of these materials is all very costly, and they take a toll on the environment.

By changing your bottle… you greatly improve your logistics operation.

The extraordinary strength and durability of BottleOne containers can be leveraged to stack more, and higher. One user went from 4 layers on a pallet to 5 layers on a pallet, and stacks of 2 pallets in the same space formerly used for 1 pallet of HDPE bottles. Product storage, handling and shipment is streamlined, and efficiency is improved at every step.

By changing your bottle… milk, juice, laundry detergent and other products will be e-commerce ready and drone deliverable.

There is exciting growth happening in e-commerce, and that growth is in its infancy. Participating in that growth requires a package with the toughness of BottleOne. Most HDPE bottles do not have the performance characteristics to shine in the e-commerce industry, as even a small leak will contaminate other products, other shipments, and the delivery vehicle itself.

By changing your bottle… your product will command higher prices at retail.

Walk down any grocery store aisle and you will see how consumers value PET bottles vs. traditional HDPE bottles. Across every retail channel, products are worth more in PET than in HDPE (in many cases, identical products). PET looks better, products taste better, and the overall performance is better than in HDPE.

By changing your bottle… self-manufacturing becomes an option.

BottleOne technology is designed for in-line, on-demand production. BottleOne PET containers can be made faster than HDPE to match filler speeds, with significant savings from space utilization, labor content, energy, waste, and work-in-process. Most customers find a favorable payback when adapting their production line to incorporate BottleOne containers.

By changing your bottle…

We can introduce you to a 21st century operating model

Manufacturing

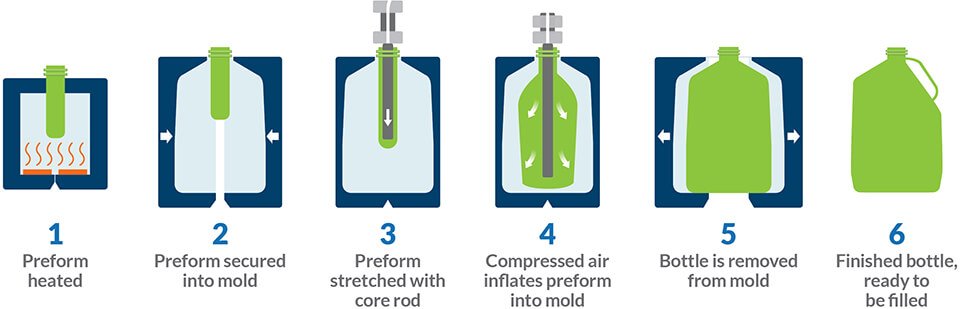

A revolutionary blow molding processBottleOne Technology builds on the principles of injection and reheat stretch blow molding to create PET containers of extraordinary strength and durability. Using a preform with an integrated PET handle, BottleOne technology uses established manufacturing platforms to create large capacity handled containers at industry competitive speeds and economics.

Patented Technology

The development of BottleOne, a PET bottle with an integrated PET handle, took nearly a decade. Currently, there are eight US patents which have been issued, and three US patents that are currently pending. To date, there has never been a patent claim denied. The initial patent “Manufacturing Method and Device for a Container with an Integral Handle” has been approved in 8 countries and has been allowed and is now pending in over 20 countries.

Independent top load strength tests demonstrated BottleOne was far superior (>7x) to HDPE bottles in a side-by-side evaluation of one gallon bottles. Virginia Tech has validated BottleOne to have a higher retention of riboflavin (flavor), vitamins, and dissolved oxygen (potential for longer primary shelf life).

8 US PATENTS and 3 US PATENTS PENDING

APPROVED IN 8 COUNTRIES AND PENDING IN OVER 20 COUNTRIES

Making a BottleOne PET bottle

Preforms

- BottleOne is your source for preforms that take advantage of the BottleOne technology.

- BottleOne offers volume pricing, continuous technological improvements, and the ability to quickly and easily adopt this innovative operating model.

- Preforms can be manufactured with up to 100% recycled PET.

- A variety of stock and custom sizes are available.

- All BottleOne product is 100% recyclable.

Blow molding

BottleOne containers are manufactured utilizing a reheat stretch blow molding process on industry standard blow molding equipment modified for the technology. No ancillary equipment is required to apply or attach the handle.

Blow molding process

Industrial design services

We provide industrial design services, including product testing, engineering design, and industrial design consultations for consumer plastic containers.

Incredible partnership

InterTech has been engaged as our exclusive engineering integrator, for design, installation and project management of all production line conversions to BottleOne.

InterTech has helped hundreds of food and beverage plants implement a variety of manufacturing projects for over 35 years. InterTech helps manufacturing companies reduce their operating cost for a single line or for multi-plant operations. They model plant operations and provide feasibility analyses of project ideas.

InterTech also develops Requests for Information (RFIs) or Requests for Proposals (RFPs) for major equipment to determine and secure the best value for its clients. InterTech can forecast operational costs for the long-term and establish budgets for plants that have not previously been self-manufacturing their bottles.

InterTech’s clients include Coca Cola and Pepsi Cola (and their respective bottlers), Cargill, ADM, Refresco, and many others. We invite you to view a more complete list of InterTech’s esteemed past and current clients.

Meet some of the experts

With decades of relevant experience in PET bottle manufacturing, we’re collaboratively solving all potential roadblocks to implement BottleOne technology.

Bill Duelge

Chief Technology Officer

Brian Lynch

Chief Financial Officer

Gregory A. Kershner

Chief Executive Officer

Mike Cunningham

Business Development

Blog

Post-Consumer Recycled Plastic Crisis Leads to Attaining PCR Goals

Recently I’ve been asked about the use of post-consumer recycled plastic (PCR) in BottleOne PET containers. PCR is a subset of rPET, which is recycled PET. PCR comes from bottle recovery programs such as curbside recycling and bottle deposit channels. Here are my...

BottleOne Technology Featured in SIPA Presentation

If you didn’t tune into PETnology’s Pack Passion Week 2022, you missed a good one. Even though I like the personal touch of being at the conference, I enjoyed watching the presentations from my desk. SIPA’s presentation, by Paolo De Nardi and Pablo Fiorentini, was my...

New PET Packaging Sensation – BottleOne

Before I get into the specifics of the new PET packaging sensation, BottleOne, I want to take you back a few years. For those of you old enough to remember the influential music critic, Jon Landau, when he first saw Bruce Springsteen in Cambridge back in 1975, he...

BottleOne’s PET Bottles Critiqued by Plastics Expert, Chris DeArmitt, PhD, FRSC

If you are a regular reader of our blog, you know we are passionate about our BottleOne PET bottles. BottleOne is an affordable large capacity, standard grade PET bottle with an integrated PET handle. Our unique handle is integrated and molded into the preform (it is...