The dairy industry continues to be in a state of disruption. Competition increases while the growth forecasts decrease. Sluggish growth as a result of the pandemic adds to the complexity of an already strained market. Now more than ever, it is important for companies selling milk to revisit their operational models and find ways to increase dairy profitability.

BottleOne can help. By replacing your large capacity HDPE bottles with BottleOne standard grade PET bottle technology with an integrated PET handle, you can gain the competitive edge you need during these unusual times.

There are 7 proven ways BottleOne can help to lower costs and increase dairy profitability.

- Higher Retail Value

- Lowest Cost Production

- Increased Efficiencies

- On-Demand Manufacturing

- Reduced Secondary Packaging

- Reduced Transport Packaging

- Reduced Unsaleables

You can visit BottleOne to read about the specifics of each of these areas. In this article, we are going to focus on number 3, which is increased efficiencies.

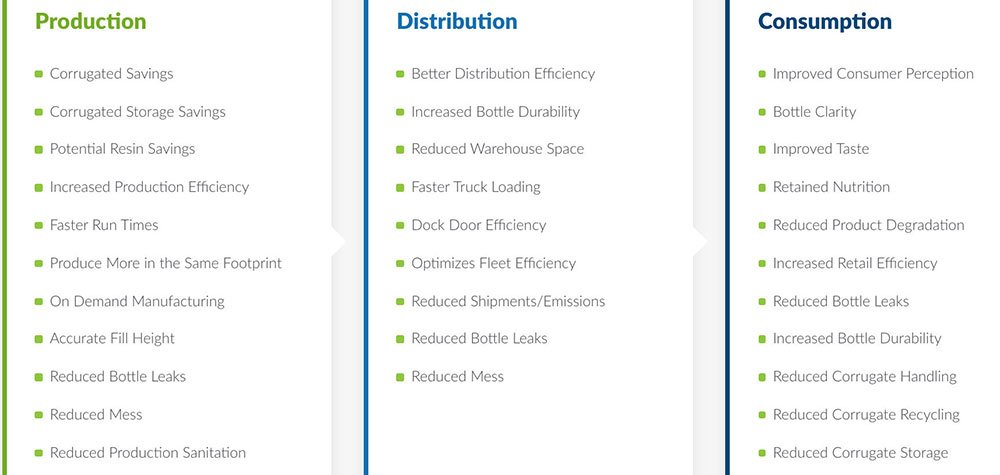

As you can see in the chart below, the savings offered by BottleOne impact every aspect of the supply chain. We’ve chosen to feature just three of the many examples.

Increase Dairy Profitability by Using a High Precision PET Bottle

The best analogy to describe this is a 2-liter bottle of soda.

A 2-liter bottle of soda combines a high precision PET bottle, a high precision cap, and a hermetic seal.

The carbonation in soda requires the seal of the bottle and cap to fit in such a way that no air or liquid can escape from the bottle. Using this same technology, BottleOne can prevent leaks and reduce spoilage of milk.

Additionally, when you are in the soda aisle of the supermarket, you will see that all the bottles are exactly the same for each soda brand. There are no deviations.

This allows for precise volume filling of the product.

Now let’s talk about a dairy example. A typical dairy has 3 gallon lines and one half gallon line to make the HDPE bottles. If you look at the bottles on those lines, each gallon bottle is different. Unlike PET, there is a lot of deviation in HDPE bottle size.

When you pick up an HDPE bottle in the store, you’ll notice a round depression in the side of the bottle. That depression is a fill plug. Every year as the mold shows wear, the bottle gets bigger. In order to prevent giving away extra product, they increase the size of that plug. You can tell how old the mold is based on how big the plug is.

PET molds don’t wear like HDPE. PET molds hold their shape and provide consistent bottles from line to line, region to region, no matter how old they are.

Since each HDPE bottle is different, they are oftentimes flood-filled. This means the producers fill the bottles to the top and let them overflow into the production facility. The excess product has to be washed down the drain using chemicals for sanitization.

With HDPE, there isn’t a precision bottle, a precision cap, or a precision fill level. By switching to BottleOne’s PET milk container, flood-filling goes away, along with all the headaches that come with it.

The Strength and Durability of PET Can Also Increase Dairy Profitability

Let’s go back to our 2-liter soda bottle example. You’ll notice, the crates that Coke or Pepsi use for their 2-liter bottles are low profile shipping containers. They are able to use those crates because of the strength and durability of the PET bottles.

Full-depth milk crates are required for HDPE bottles since there is very little strength or durability in HDPE. The crates have to bear all the weight and support because the bottles can’t. The HDPE bottles themselves can be easily damaged.

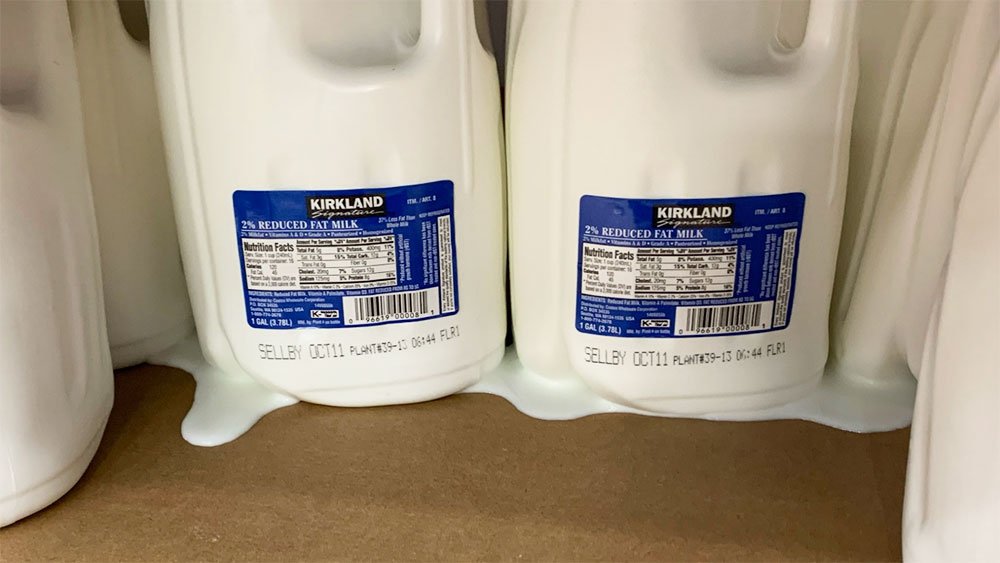

Also, since there isn’t a hermetic seal on HDPE containers, if you put weight on them, the product will come flowing out. In most retail stores, you can see the milk that has flowed out of the HDPE containers. It is in the bottom of those trays or in the corrugated boxes.

With BottleOne, the secondary packaging can be greatly reduced. Crates can be reduced in size to one third or even eliminated altogether. The reduction in packaging and clean-up will definitely help you to increase dairy profitability.

Wrap Up

When you start manufacturing using BottleOne’s technology, the very first benefit is that every bottle will be stronger and more durable than HDPE milk jugs. This means no more leaks, mess, or clean-up in production, transportation, or the dairy case.

By incorporating BottleOne’s hermetic seal, flood-filling or loss of product will no longer be necessary. A dairy can lose upwards of 2% of their product due to flood-filling because they don’t have a precision bottle to sell to the consumer.

2% is mind-blowing when you think about it!

In addition to saving that 2%, there is also the cost savings of the chemicals and labor used to wash the milk down the drain and to clean the milk from the outside of the containers.

This is why the supermarket cleans their dairy cooler daily, and why the checkout conveyor belts need sanitizing. Once the milk gets on the outside of the bottle, it ends up everywhere.

By preventing milk from leaking onto the outside of the bottles, the smell is also eliminated. We could go on and on. Continuing to use HDPE is continuing to use a 55+ year old technology.

We have barely scratched the surface for how BottleOne can help you to increase dairy profitability. This is just the filling part of the story.

We hope you’ll click over to more of our blog posts. Each one provides more detail about how BottleOne can improve your operating efficiencies and profitability.

Let us show you how BottleOne will improve your operating efficiencies and increase your profitability

BottleOne is an affordable large capacity, standard grade PET bottle with an integrated PET handle. BottleOne is designed to dramatically impact your supply chain. Let us introduce you to this 21st century operating model.

0 Comments